Why Ultrasonic Cleaning?

Deeper. Safer. More Effective.

Traditional bake-and-blow methods rely on extreme heat and air pressure, which can weaken substrates and leave behind embedded ash. Ultrasonic cleaning uses high-frequency sound waves in a controlled liquid bath to penetrate deep into microscopic channels—removing contaminants evenly and non-destructively.

DPF Cleaning

Benefits include:

Removes ash, soot, oil residue & DEF crystallization

Cleans deep within honeycomb cells

No thermal stress or cracking

Restores airflow and reduces backpressure

Extends DPF service life

Results you’ll see:

Fewer regens

Improved fuel efficiency

Lower exhaust temperatures

Reduced risk of forced derates

Other emission parts we clean:

DOCs - Diesel Oxidation Catalyst

EGRs - Exhaust Gas Recirc Valves

SRCs - Selective Catalytic Reduction

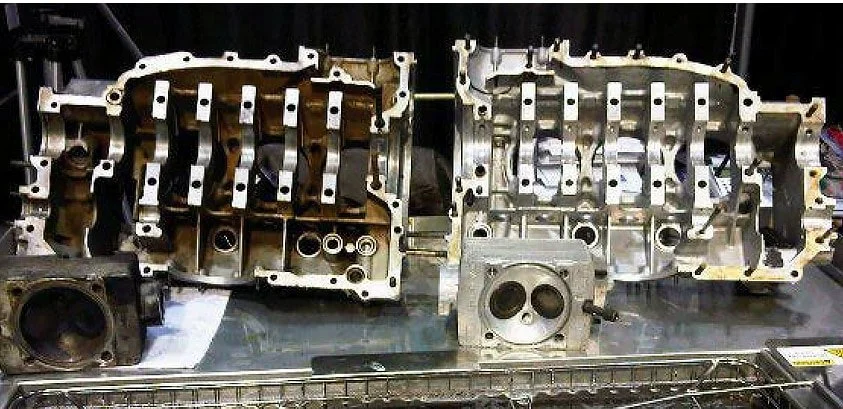

Large-Part Ultrasonic Cleaning

Our industrial-scale ultrasonic system allows us to clean large and complex components that conventional methods can’t handle.

Fuel injectors

Fuel lines

Gearboxes

Metering valves

Oil hoses

Coolant hoses

Piston seals

Radiator parts

Spark plugs

Throttle bodies

Transmissions

Valve parts

Alternators

Starters

Bearings

Gear sets

Brake parts

Carburetors

Clutches

Pressure plates

Cylinder heads

Differentials

Drivetrains

Filters